Assemblies and subassemblies

Rolling stock subassemblies

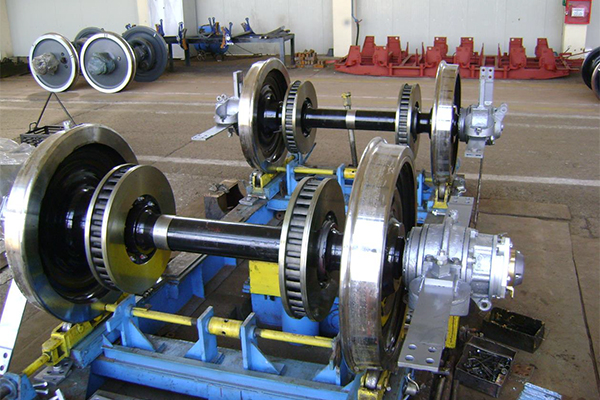

- Axles - processing, assembly, repair, measurement and verification

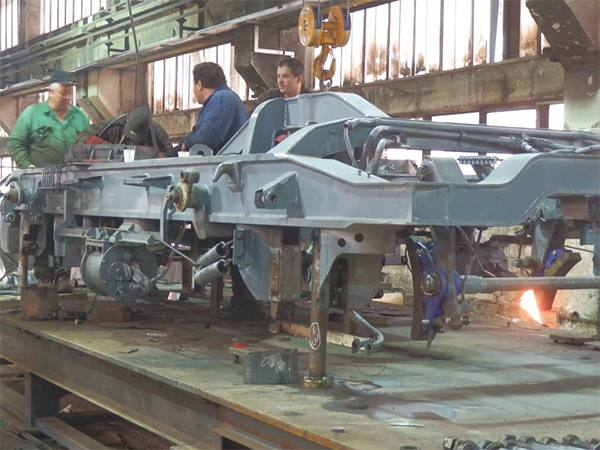

- Bogie frames – machining subassemblies, welding, stress relief, sandblasting, measuring, painting

- Underframes - processing subassemblies, welding, sandblasting, measuring and checking, painting

- Car bodies - subassembly processing, welding, sandblasting, measuring and checking, painting

Rolling stock spare parts

- Traction – Binding – Collision

- 1000 kN traction hook used on discontinuous traction apparatus;

- Type O hitch

- Drawbars for motor and towed railway vehicles

- Binding device for standard gauge railway vehicles

- "F" type drawbar

- Type F drawbar with two threads

- Buffer stroke 75 mm, for freight wagons with normal gauge

- Buffer category A, stroke 105 mm, for freight wagons with normal gauge

- Bogie, brake, suspension

- Bolts for passenger and freight cars

- Bushings for passenger and freight cars

- Triangular axis

- Double welded brake shoe carrier for freight wagons

- Simple brake shoe carrier for freight wagons

- Archers and swinging pendulums

- Coil springs for rolling stock

- Leaf springs for railway rolling stock

- Suspension ring for freight wagons

- Clevis for Y 25 bogie

Mechanical - welded constructions with dimensions up to 26.10 x 2.89 x 3.22 m, 13.6 t., incorporating electric and pneumatic mechanisms for related industries: machines - tools, automotive, agriculture, etc

Projects:

- Execution of 21 car bodies for Morocco

- The execution of two railway vehicle car bodies for Austria

Services for the rolling stock industry and related industries

Subassembly processing:

- Blasting of cast, molded, milled parts and quenching of helical and sheet springs. Maximum weight of parts/molded landmarks from 6 to 100 kg; Blasting sheets and profiles, maximum size: 6,000mm x 3,000mm

- Sheet metal cutting

- Cutting bar-type laminates (CNC vertical saws type KASTO)

- Guillotine shearing (CNC TruShear series 3163 – TRUMPF)

- CNC bending

- Machining by chipping

- Hot processing

- High frequency current treatment- pieces of revolution

- Laser marking and percussion

- Automated line for manufacturing helical springs, maximum bar diameter Ø 36 mm; G+M Dorn spring mounting surface polishing machine; Test stand for helical and leaf springs, with Zwick test protocol, force 170kN, spring diameter Ø 500mm

- Specialized line for processing axles and wheels

- Measurement and control